~

THE BLADE: TOLEDO,OHIO

Will Somers' wave of success

Continued From Page 8

again later down the line. In

an orderly, mechanized process, the wood becomes tables. In one area alive with

the sound of metal conquering wood, hardwood boards are cut into legs, tops,

drawers, and shelves with huge saws and lathes.

On another floor,

exotic woods for veneer - circassian walnut, rich mahogany, carpathian elm - are

sliced paper-thin. Veneers are created in layers, with the top decorative sheets

matched for grain and color and glued in place, then put through heat presses

for bonding to sub-layers.

When all the

pieces are glued, pegged, and screwed into place, and the veneers applied, the

new tables move to the top floor for finishing. There they are sanded, dusted,

stained, rubbed, varnished, and rubbed some more. From rough board to finished

table, the process now takes about 12 weeks, much of that used in seasoning the

wood.

"We use a lot of Ohio materials," Mr. Somers points out. In

addition to the wood harvested from the eastern part of the state, Ohio glass

and paper packing products are used. Mr. Somers also has tapped Ohio industry

for technical assistance in what is the most revolutionary change to move into

this century-old industry. It is a change that should help Mersman continue to

prosper in the competitive furniture market by producing individual orders in

smaller numbers.

THE company is well into a $10 million overhaul of portions

of the production line that Mr. Somers hopes will go on-line in less than two

years. "We want to automate the plant. We'll use computer-controlled machines,"

the president says. "No one in the woodworking business is doing

this.

"Our new plan won't affect the finishing, but it will

affect the fabri- cating. We don't want to be able to make more of larger

amounts. We want to make smaller amounts. We want to have a focus factory," the

president says. He wants to cut production time to 6 weeks.

Study trips have

taken Mr. Somers and his planning staff to the Whirlpool plant in Clyde; the

Ohio Art Co. in Bryan, and to the Honda plant in Marysville. "Honda can build a

car seat in three hours. Can Mersman Waldron build a chair that quickly?" Mr.

Somers asks.

Although sales have doubled since he took over the

company, the president notes, "In Celina, we have a lot of work to do if we're

going to continue growth in Ohio. Our employment is down, but we hope to bring

it back." He has asked the state for financial assistance in executing the

plans.

MONDAY, JULY 4,1988

-

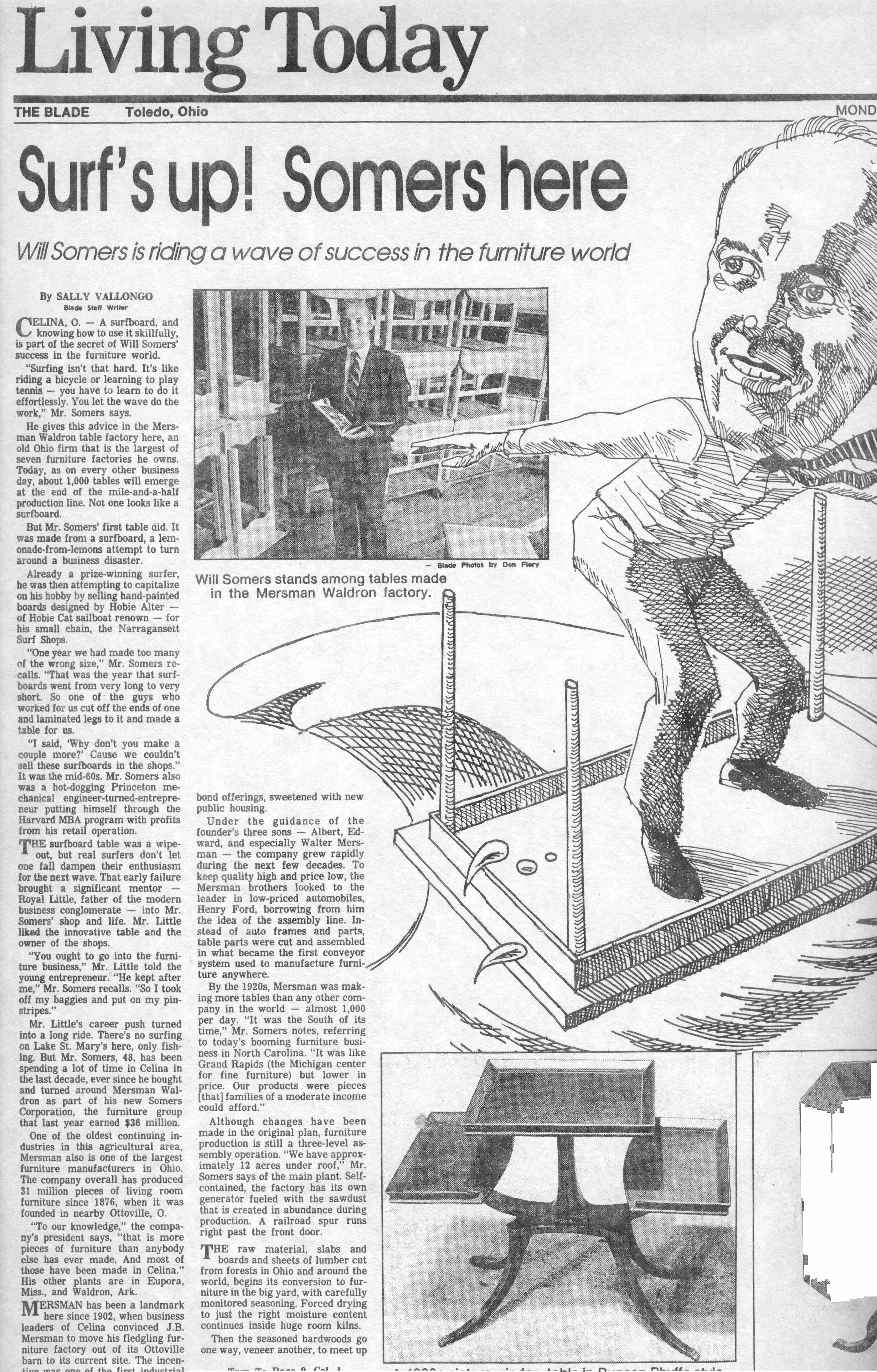

Blade Photo by Don Flery

Will Somers found this 50-year-old piecrust table in a

country store when he began acquiring pieces of company history for a new

Mersman museum

he

started

in Celina.

Mersman's products today are still aimed right at the middle of the furniture market. The current lines include traditional, contemporary, country, oriental, and transitional styles in a wide range of upholstery fabrics and finishes. Mr. Somers works closely with his designers to steer the lines.

"I do have a sense of design, probably partly innate, partly training. You learn to look at something in sketch form and know what it will look like when it's made up," he says. He is proud of the way his seating and tables work together - the way an end table meets sofa at just the right height to support an elbow, for example.

User studies have led Mersman to make its sofas slightly higher to suit men, who most often choose them, and side chairs slightly lower to accommodate women. "We want it to be easy to live with. We try to realize someone's expectations. We plan the furniture to be responsive to those expectations.

"You try to build a system to give people building blocks to use in creating their homes. We believe furniture should not look as if it was all purchased at the same time."

MERSMAN WALDRON is taking advantage of the newest ideas in marketing as well as manufacturing. The gallery system of display- ing furniture by one maker in a room-like setting is being supplanted

by smaller focus stores that offer the company's entire line of home furnishings. Called Comfortables, the Living Room Store, they are going into regional malls to fill the gap created by vanishing department store furniture departments.

And the ultimate arrangement, computerized ordering that will lead to rapid production of exactly what the customer has ordered, is not that far away, Mr. Somers believes. "We've come a long way," he says with obvious pride.

Moving quickly through the huge plant, his horn-rimmed spectacles slipping down his nose, the energetic president is all business, mixed with quick greetings - always by first name of every employee he meets.

But mention his old love - surfing - and a change occurs.

Off come the glasses, the posture relaxes, and it's not hard to picture this pin-striped executive back in his baggies, hanging 10 on a board, cruising down a breaker for a long ride. That vision is not far from the truth, it turns out. Mr. Somers hasn't abandoned his first love.

His home and family are in Rumson, N.J., not far from the waves. "I still surf. 1 still compete," he says, his eyes lighting up, his tan seeming to darken. "Last year I came in 5th in the eastern division in my age group. "